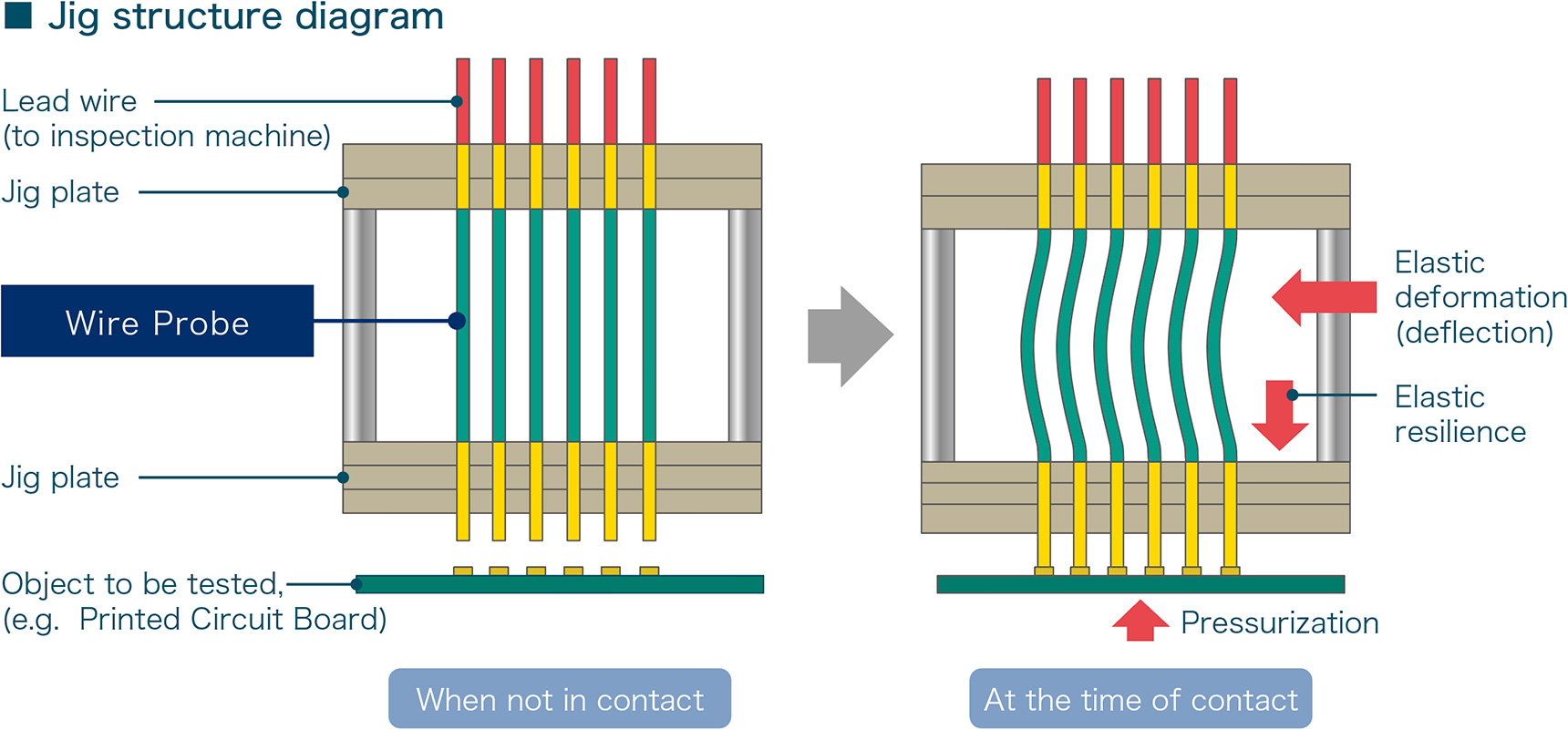

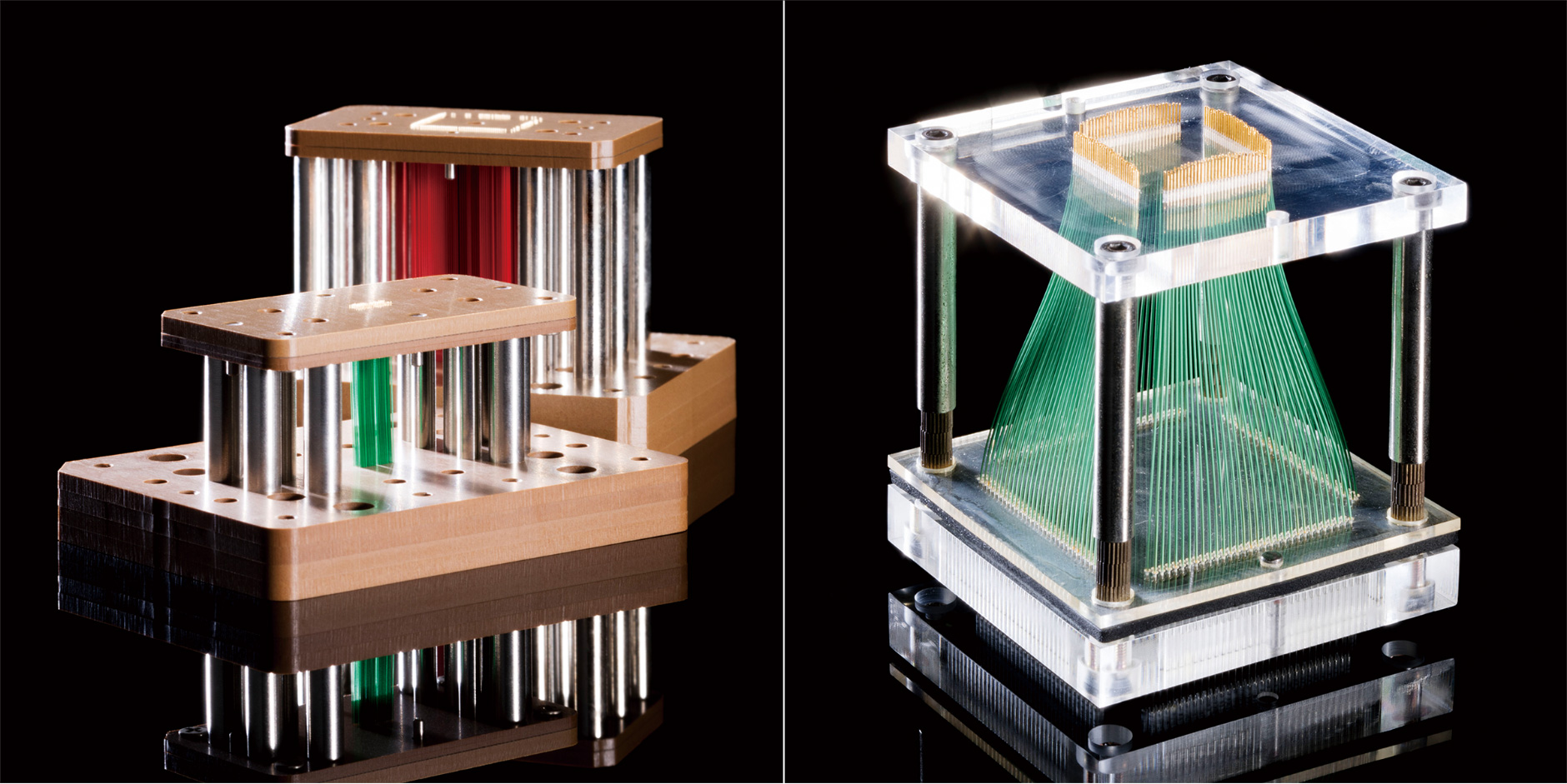

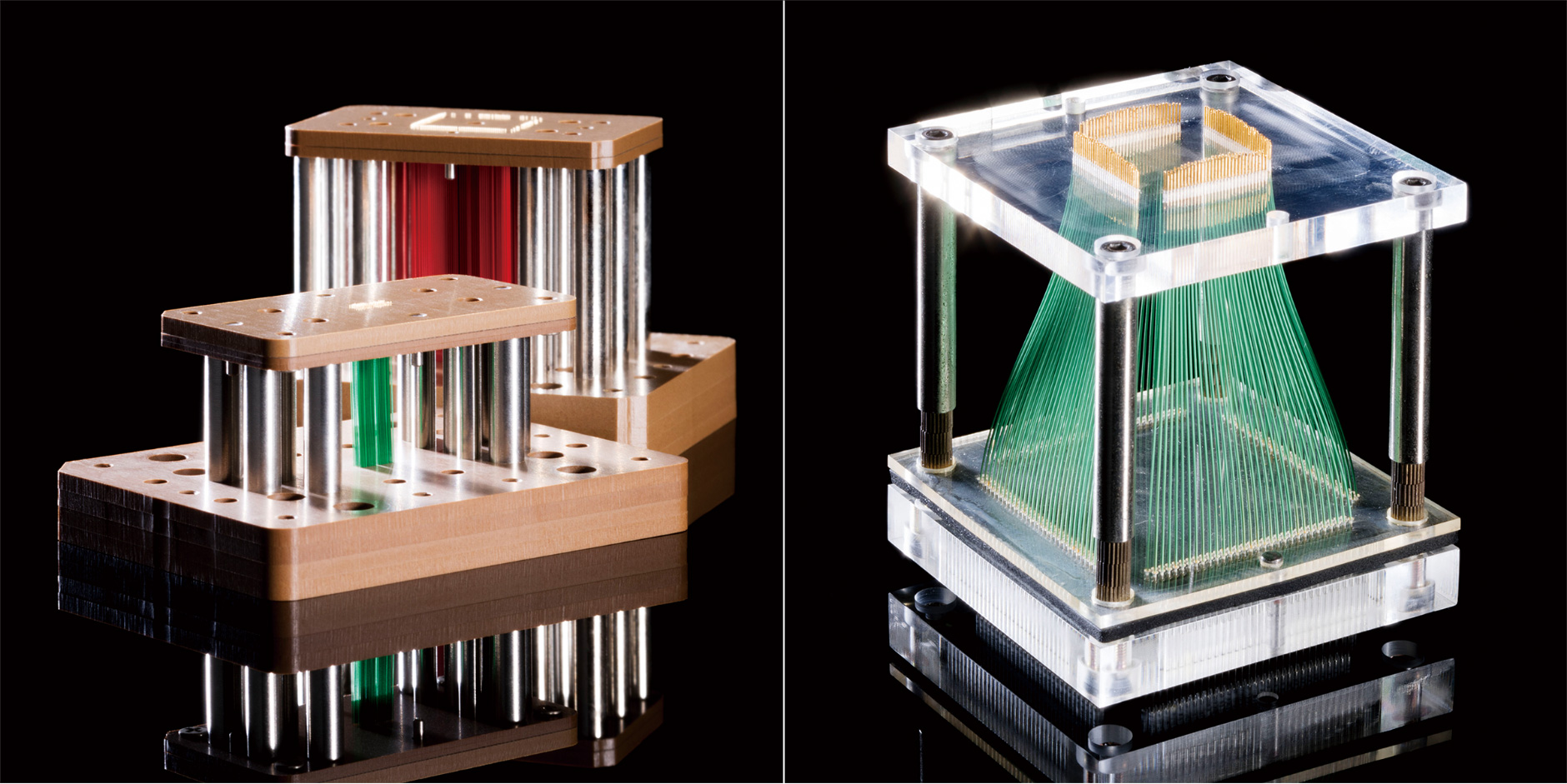

Wire probes with elasticity in the probe itself are commonly referred to as “Needle Probes”. The structure of this probe is simple, and the probe itself has springiness by using a special highly elastic wire. When pressure is applied to the probe, pin pressure is generated by utilizing the elastic deformation and restoring force of the wire body.

Applicable to 45μm pitch*

It can be used for electrical inspection of narrow pitch electrodes, which are difficult to handle with spring probes.

*When using Ф0.02mm

Excellent spring

Characteristics

An integrated probe ensures stable load. Taking advantage of the spring characteristics, it rises sharply up to a certain stroke and stabilizes at strokes higher than that.

Durability test cleared

1 million times

With the Ф0.3mm probe, durability test was cleared 1 million times in our factory. Compared to spring probes, the structure is simpler and more durable.

Pin pressure is determined by the material (hardness), wire diameter, and the distance between the fixing plate and the guide plate. Also, as a spring characteristic of the wire probe, unlike the spring probe, it rises sharply up to a certain stroke and stabilizes at higher strokes than that. However, if the stroke exceeds “Elastic limit” of the probe, the pin pressure will conversely decrease. Use in this area may result in the non-recovery of the wire probe and should be avoided.